Founded in 1973, Samsung Electro-Mechanics has developed and produced core electronic components, increasing the competitiveness of the Korean electronics industry and growing into a partner of global electronics, IT, and automobile companies. Let's look back on what happened in September in the history of Samsung Electro-Mechanics since 1973.

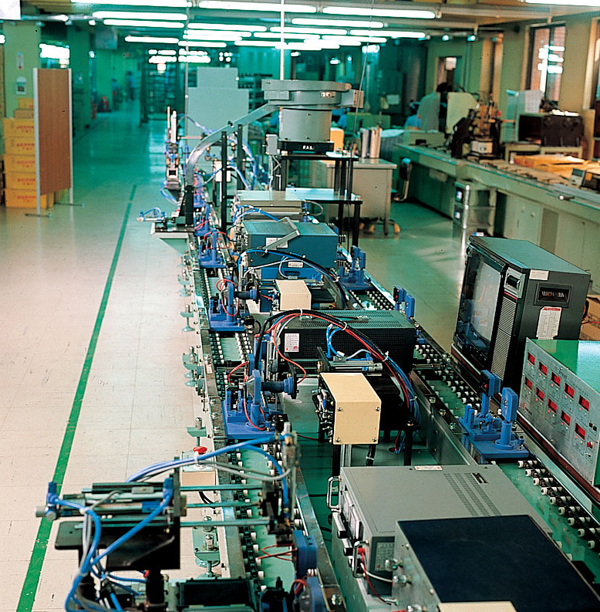

1986ㅣDeveloped an automated FBT line

In the late 1970s, Samsung Electro-Mechanics recognized the importance and necessity of automation and stepped up related efforts. We worked to achieve technological improvements, such as on-site facility preservation, mold production, design, and assembly, and successfully automated the flyback transformer (FBT) production line in 1986.

FBT is a part that supplies voltage to the anode of cathode-ray tube (CRT) of TVs or monitors. With the increasing demand for color TVs and monitors from the mid-1980s, the demand for FBT also jumped by more than 25%. In 1986, the development of an automation production line was considered as a continuous demand increase was expected.

This led to significant progress in improving the productivity and quality of FBT as well as reducing the defect rate. It was also significant in that it was the achievement of our own automation technology, the first of its kind in Korea.

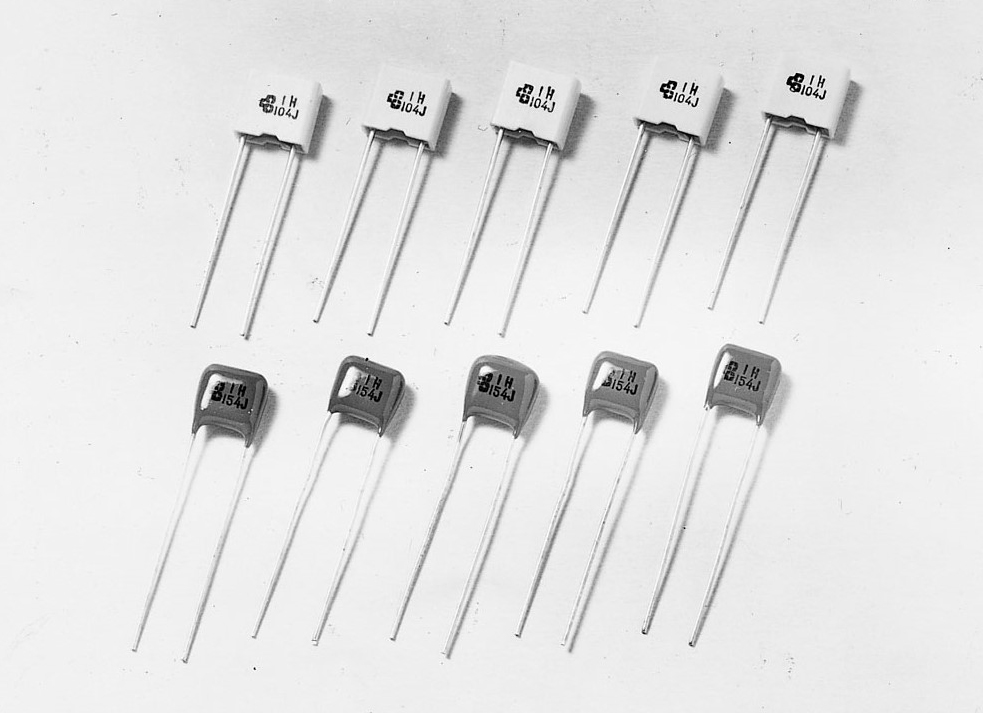

1990ㅣDeveloped MLFC

In 1990, we developed Korea's first multi-layer film condenser <!--[if !supportAnnotations]-->[31] (MLFC), built a facility with a production capacity of 3.5 million units per month, and started mass production. MLFC is an essential part to make electronic products light, thin, short, and small and develop surface mount devices (SMD). Samsung Electro-Mechanics succeeded in developing MLFC with its own technology in two years and six months after investing KRW 1.2 billion in R&D in 1988.

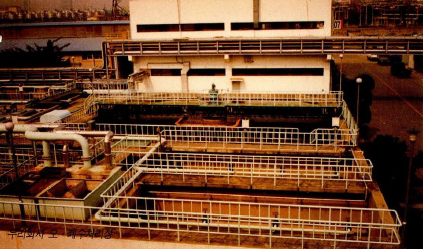

1996ㅣ Became the first electronic parts company to acquire ISO 14000

In 1996, Samsung Electro-Mechanics became the first Korean electronic parts company to acquire ISO 14000, an international standard for environmental management systems. We were also the world's first company to be certified by UL, an independent certification body in the United States. ISO 14000 is a series of environmental management standards, based on which the International Organization for Standardization (ISO) evaluates a company's environmental management capabilities.

To achieved this, Samsung Electro-Mechanics formed the Environmental Management System (EMS) task force in 1995 and engaged in activities such as the use of pollution-free energy, the replacement with environmentally friendly organic solvents, and the establishment of a continuous monitoring system and remote control system for water quality improvement. With ISO 14000, Samsung Electro-Mechanics was able to build an eco-friendly business structure and actively respond to international trade barriers.

2000ㅣThai subsidiary won the Prime Minister's Award

Samsung Electro-Mechanics' Thailand subsidiary won the Prime Minister's Award 2000 in the productivity category from the Thai government. The Prime Minister's Award selects and awards the best-performing companies every year in the four categories of productivity, environment, safety, and quality among manufacturers in Thailand. This award is recognized as the highest honor in the Thai manufacturing industry. Our Thai subsidiary won the Prime Minister's Award for the third time following 1995 and 1998, and Samsung Electro-Mechanics was the first to receive the Prime Minister's Award three times since the establishment of this award in 1993.

2013ㅣSigned an MOU in support of an orchestra of children with disabilities

On September 5, 2013, Samsung Electro-Mechanics and a children’s foundation signed an MOU for "Hello, SEM! Orchestra." "Hello, SEM! Orchestra" is Samsung Electro-Mechanics’ social contribution program that supports the rehabilitation and self-reliance of the disabled through music. "Hello, SEM! Orchestra” consisted of 35 students with disabilities from the third grade of elementary school to the second grade of high school, and Samsung Electro-Mechanics sponsored the training and operation of the orchestra.

2014ㅣRenovated the main gate of Suwon Plant

The main gate of Samsung Electro-Mechanics' Suwon Plant was renovated three years after the gate column was first built. The four values of Co-Creation, Synergy, Total Solution, and New Experience were reflected in the column as we aimed to be a total solution provider that provides new experiences and creates values.

In 2020, "RiGHT," Samsung Electro-Mechanics’ new core value, was engraved. Learn more about Samsung Electro-Mechanics' mission, vision, and core values at the link below.

Go to Company introduction >

2019ㅣHeld Tech-Day with automotive MLCC customers

The 2019 Samsung Automotive MLCC Tech-Day was held with Korean automotive customers. This event, held at the Busan Plant, was the first official promotion held for domestic customers and attended by about 100 executives and employees of major electronics companies. Samsung Electro-Mechanics introduced its various automotive product lineups and the principles, market conditions, and industry trends of MLCCs.

Samsung Electro-Mechanics has been manufacturing industrial and automotive MLCCs since 2016, and has built and operated a production line dedicated to automotive MLCCs in Busan. More recently, the company developed MLCC for advanced driver-assistance systems (ADAS) and received the Bosch Global Supplier Award from Bosch, an auto parts company.

2020ㅣDeveloped the world's smallest power inductor

Samsung Electro-Mechanics developed the world's smallest 0804-size (0.8mm wide and 0.4mm long) power inductor in 2020. Compared to the 1210 size (1.2mm wide, 1.0mm long), which was the smallest among the existing products for mobile devices, the new product is ultra-compact with a significantly reduced area and a thickness of only 0.65mm.

The power inductor is a core component necessary to supply stable electricity (power) from the battery to the semiconductor, which is essential for smartphones, wearable devices, and electric vehicles. Samsung Electro-Mechanics, which has been developing and producing inductors since 1996, is increasing its market share with the industry's best technology on raw materials and ultra-fine manufacturing.