World-Class Camera Module

The camera module is a product used to take photos and videos from mobile devices, such as smartphones, automobile, and smart

home appliances. In all areas, a high level of technology is needed that requires high resolution, miniaturization, slimming, low-power,

and high stiffness. Samsung Electro-Mechanics designs and manufactures core components such as lens, actuator, and PCB in-house.

As the only company equipped with all of the major core technologies for designing and manufacturing world-class camera modules,

we produce camera modules for mobile devices and automobiles.

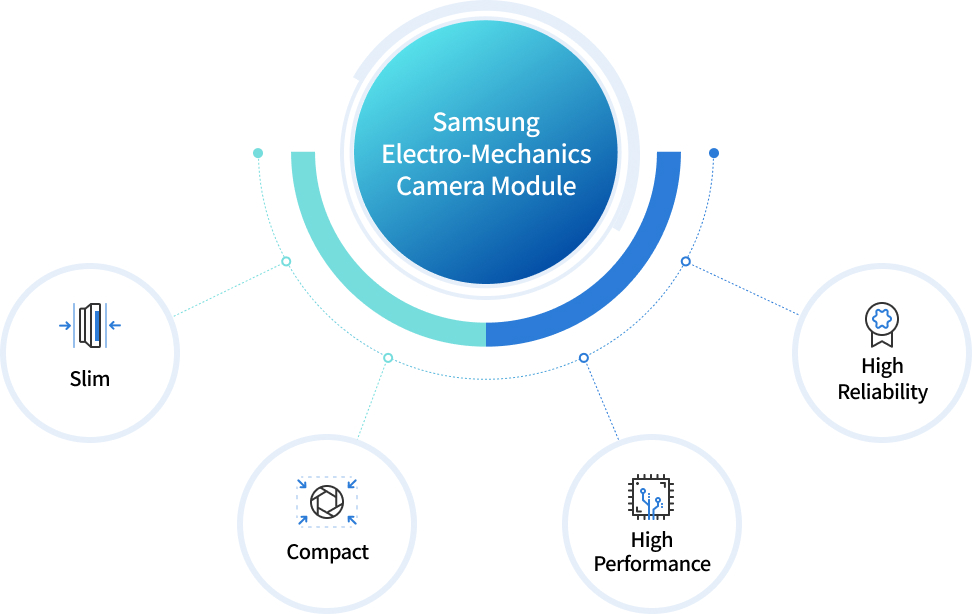

Samsung Electro-Mechanics Camera Module

- Slim

- Compact

- High Performance

- High Reliability

-

- Lens

-

Slim Bright Lens

High CRA

-

- SW

-

AF/OIS

Image Examination Calibration

-

- New Tech.

-

Multi Camera

New Actuator

New Lens

-

- Manu-facturing

-

Full Automation

High Cycle & Assemble

Low Tilt PKG Tech.

-

- Synergy

-

PCB, Mold, Drive IC

FA (Failure Analysis) tech.

-

- Sensor

-

Evaluation Sensor

Performance

New Sensor Tech.

-

- Zoom

-

High Performance

Optical Zoom

-

- OIS/AF

-

High Performance

OIS/ Closed Loop AF

Ball Guiding Act.

Main Core Technology

-

- Actuator

-

A component in a camera module that

moves the lens up and down or left and right

at high speed to focus or stabilize images.

-

- Lens

-

A component that collects the light emitted

from the subject and delivers it to the image sensor to

form an image of the subject.

-

- PCB

-

Comprised of a combination of various materials

such as PSR, copper foil, and insulators,

and transfers digital images through

organic circuit operation between components.

-

- Mobile PKG

-

A technology that optimizes camera module performance

by mounting, assembly, and inspection/evaluation

of optical components.

Curation

Sign up for our newsletter to receive news and valuable information

about Samsung Electro-Mechanics.

FAQ

-

When you go to the Contact us on the main page or the Product page, you can ask questions about technologies and purchases by each region.

-

It serves the role of re-collecting the light emitted from the subject to form an image on the image sensor.

-

When the number of lenses increase, the refraction angle for each lens decreases, which can reduce the spread of light. Because high resolution has smaller pixels, the core technology is to create the image without the spread of light.

-

Unlike previous circular lenses, the D-Cut Lens is a lens that has cut the top and bottom areas, and it is advantageous in that it can minimize camera module size.

-

It is a factor that determines the amount of light that enters the lens by combining the focal distance of the lens with the caliber. When F# is smaller, you can obtain a brighter photo.