- ▶ Plan for mass production of automotive camera modules equipped with market-leading water-repellent and heating functions

- ▶ Securing super-gap technology by internalizing key components of camera module technologies such as lenses and actuators

- ▶ Automotive camera modules grow at an average annual rate of 13.8% from USD 3.1 billion in 2023 to USD 8.5 billion in 2030

- - Expected to install from 4 to 5 to about 20 modules per vehicle, with a continued growth in payload capacity

Samsung Electro-Mechanics introduced an all-season, weather proof automotive camera module equipped with market-leading water-repellent coating technology and heating function. The automotive camera module is planned to be mass produced within the year.

Compared to IT camera modules, automotive camera modules require high reliability. Unlike IT cameras, the stability of automotive cameras varies depending on their operational status. In other words, since the cameras must operate even under poor conditions, high reliability is required.

The automotive camera module presented by Samsung Electro-Mechanics is a weather proof automotive camera module that runs stably even in bad weather conditions such as snow, frost, and fog.

[Technical features of Samsung Electro-Mechanics’ all-season, weather proof automotive camera module]

- The world’s highest performing water-repellent coating

Water droplets left on automotive cameras can reduce driving stability, including lane changing and motion detection. It is important that water droplets are quickly removed from the lens.

Samsung Electro-Mechanics developed the water-repellent coating technology that maximizes water repellency angle and minimizes the area where water droplets contact the lens, making it easier for water droplets to fly away.

When exposed to sunlight and UV rays, these coatings wear out. The water-repellent coated lenses coated with material technology developed by Samsung Electro-Mechanics last roughly six times longer than the existing products on the market, and they perform about 1.5 times better in preventing wear caused by dirt, parking scratches, etc.

- Lens heater maintains constant temperature using active temperature control

Fogging and frost can cause cameras to malfunction in the winter, which is why heated camera technology is being actively researched to avoid such issues.

In order to ensure safe autonomous driving, demand for automakers to install heated cameras is increasing. Samsung Electro-Mechanics’ technology heats the lens to maintain a constant temperature at all times – if there is snow or frost on the camera module, the heating operation keeps the temperature constant to melt the snow or frost in under a minute while minimizing current consumption.

[Automotive hybrid lenses for reliability and productivity]

Glass lenses, commonly used in automotive cameras, can transmit light and have a high refractive index. The lens surface is strong and scratch-resistant, allowing for long-term use, and has excellent temperature stability, making it resistant to heat. However, there is a risk of damage as it is a heavy, shock-sensitive material that can easily break. Further, the polishing processes leads to high unit costs and low productivity.

Plastic lenses primarily used in smartphone cameras can be mass-produced via injection molding manufacturing methods and are more cost-effective than glass materials. In addition, the material itself is lighter, allowing for lighter weight, miniaturization, and freedom of shape. On the contrary, plastic lenses expand and contract more than do the glass lenses due to temperature variations, resulting in performance degradation as the refractive index varies. In particular, it is difficult to secure reliability in demanding external settings such as automobiles.

Recently, automotive camera manufacturers have been developing hybrid lenses that improve the drawbacks of the two lenses while combining their advantages. The hybrid lens developed by Samsung Electro-Mechanics is expected to soon be installed in vehicle cameras such as rear/surround view monitoring in the market.

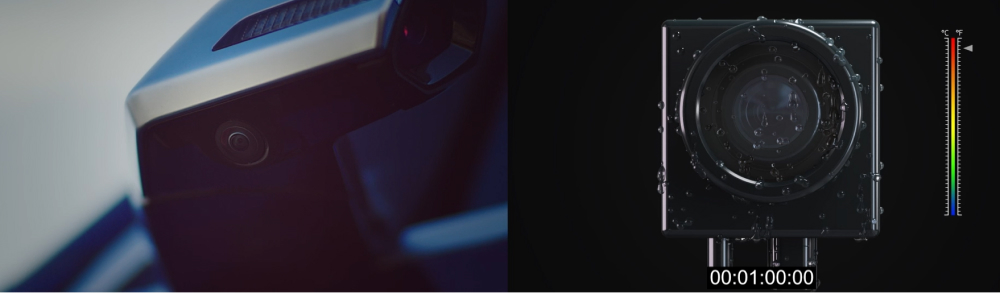

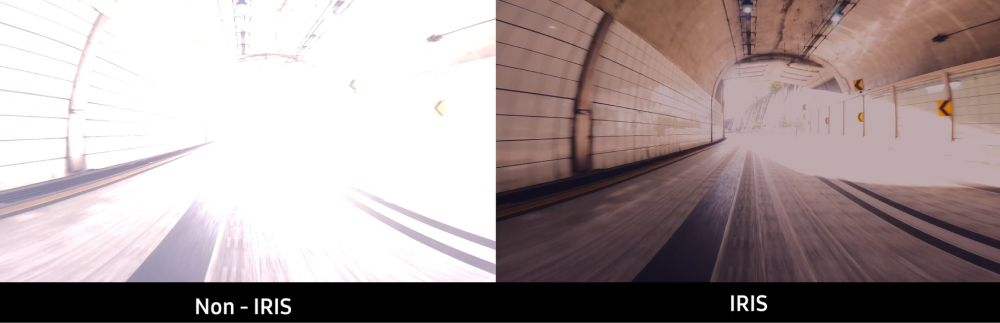

[Developed the world’s first automotive IRIS equipped camera module]

Samsung Electro-Mechanics has expanded its technology and expertise accumulated in the mobile camera module business sector to include automotive modules, providing new solutions to customers. Samsung Electro-Mechanics developed the world’s first camera module equipped with an aperture that controls the amount of light.

Expressed with an F value, the aperture is a device that controls the brightness of a photo by controlling the amount of light entering the lens. When the F value is large, the aperture is closed and less light enters, and when the F value is small, the aperture is opened and more light is let in. Thus, apertures require precise mechanism design technology to open and close the aperture with the correct amount of light.

Most apertures in mobile camera modules function at room temperature, but for automotives, they must operate flawlessly even in extreme temperatures such as -40 and +50 degrees Celsius. Using independent mechanism design technology and internalization of core components, Samsung Electro-Mechanics created the first IRIS camera module for automotives in history with guaranteed reliability.

[Securing super-gap technology by integrating core technology of IT cameras with automotive cameras]

Camera modules are widely used in industries such as smartphones and automobiles, and require advanced technologies including high image quality, compact/slim design and low power consumption, high rigidity, etc. Samsung Electro-Mechanics supplies camera modules to major smartphone companies based on the core technologies required for camera modules, such as lens design and mold technology, high-performance actuator manufacturing, etc.

In particular, innovative products that satisfy client expectations are offered thanks to Samsung Electro-Mechanics’ unique technology that directly designs and manufactures key components such as lenses and actuators. With the development and mass production of highly reliable automotive camera modules using technology amassed in the mobile sector, Samsung Electro-Mechanics is also expanding business with global automobile companies.

The industry anticipates that Samsung Electro-Mechanics will continue to increase its share of automotive camera sales, which is projected to reach 24% in 2025 from around 10% in 2023. As the specifications and number of sensing cameras for automotives are increasing, Samsung Electro-Mechanics’ sales and share of camera modules for electric vehicles are also gradually rising.

[Automotive camera module expected to grow]

The automotive camera module market is expected to grow rapidly as autonomous driving technology develops (applying from 4 to 5 camera modules per vehicle → up to 20 per vehicle, with continued growth in payload), and Samsung Electro-Mechanics is well-prepared to become a “key player” in the automotive camera module market based on its IT camera module technology (Big Sensor, Variable Aperture, Folded Zoom).

Factors that are expected to drive growth in the automotive camera module market include ▲ legislation for safety regulations ▲ ADAS/AD advancement ▲ safety and convenience such as parking assistance ▲ high resolution/high performance of camera module, etc.

According to CONSEGIC BUSINESS INTELLIGENCE, a global market research institution, the size of the automotive camera module market is expected to grow at an average annual rate of 13.8% from USD 3.1 billion in 2023 to USD 8.5 billion in 2030.